Eurecat

This project focuses on the additive manufacturing of replacement aluminum parts for automotive applications, aimed at enhancing the aftermarket industry.

RCAM unifies diverse research themes to drive innovation: from next-generation materials to AI-driven additive manufacturing, we streamline processes for sustainable future technologies and digital ecosystems.

RCAM unifies diverse research themes to drive innovation: from next-generation materials to AI-driven additive manufacturing, we streamline processes for sustainable future technologies and digital ecosystems.

The materials theme encompasses research on both metallic and non-metallic materials. Novel alloy development for additive manufacturing is a core focus of the theme, and supporting this effort is an integrated computational materials engineering approach to alloy design. Complementing novel alloys is a thorough understanding of metal powders characterisation, processing and behaviour.

Functional polymers and composites for engineering applications are also a research focus. All materials research efforts are focused on developing the next generation of competitive and high-performance materials for industrial applications.

Email: ma.qian@rmit.edu.au

This project focuses on the additive manufacturing of replacement aluminum parts for automotive applications, aimed at enhancing the aftermarket industry.

Additive Manufacturing is an enabling technology for numerous sectors including aerospace, automotive, medical, defence, mining, and energy. The Technology theme at RMIT focuses on addressing industry needs to increase the productivity and competitiveness, expand material selection, tailor material properties for specific applications, develop technology for automated post-processing, enable multi-material printing, and advance closed loop quality control. Among core technologies, the team works on powder bed fusion, directed energy deposition, materials extrusion, material jetting, and stereolithography. The technology theme works across all the additive manufacturing material systems of metals, polymers, ceramics, and composites.

Email: milan.brandt@rmit.edu.au

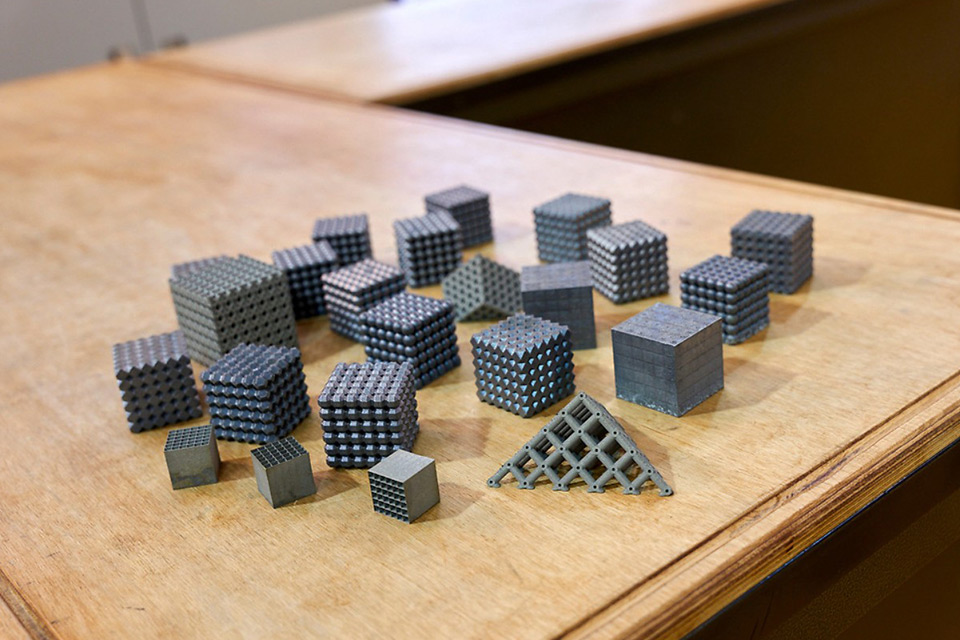

Design research at RMIT focuses on shape and topology algorithms that create functional additively manufactured parts. Our research has a strong basis in design for manufacturability, durability, and performance. The design work undertaken at RMIT interfaces with technology, and is oriented towards producing shapes that are optimised for process parameters that reduce manufacturing costs and translate to industry applications. The design team’s expertise crosses both metallic and polymer additive manufacturing technologies, including powder bed fusion, materials extrusion, material jetting, stereolithography, and directed energy deposition.

Modelling research at RMIT is used to aid the understanding of the complex physical phenomena that are produced by additive manufacturing technologies. The modelling theme encompasses the full range of processes, materials and structures. It incorporates process modelling, material microstructure evolution, and part performance. Our research is used to aid the integration of additive manufacturing technologies into Industry 4.0 practice by producing virtual models and simulating additive manufacturing processes. This approach leads to a more efficient and cost-effective adoption of additive manufacturing by reducing experimental cycles and providing assurance on part performance.

This project will develop a novel industrial process to convert PS/EPS waste into high-valued material (styrene monomer) and activated carbon by a portable energy-efficient catalytic pyrolysis reactor.

This EU-funded DIAMETER project aims to create the necessary solutions and strategies to facilitate the efficient and sustainable transition of the metal manufacturing sector into a circular economy.

This project focuses on digitalisation of Multi-Jet Fusion of polymeric components to solve the inconsistent mechanical properties observed in Multi-Jet Fusion 3D printing of automotive parts.

The "Sustainability in Additive Manufacturing" research theme at the RMIT Centre for Additive Manufacturing focuses on advancing environmentally responsible practices across the entire AM lifecycle, spanning from digital model design to material selection, from process optimisation to end-of-life pathways management.

This theme covers metal, polymer, and concrete AM, with key objectives including the development of sustainable feedstocks, energy-efficient printing methods, and circular economy strategies. Research efforts explore innovative material formulations, such as recycled or bio-derived polymers and low-carbon metal alloys, while also investigating design strategies like topology optimization and part consolidation to reduce material waste. Process-level improvements, including in-situ monitoring, closed-loop control, and AI-driven defect prediction, aim to enhance resource efficiency and minimize energy consumption and carbon footprint.

Additionally, efforts to improve powder recyclability, reduce post-processing requirements, and integrate digital twin technology further support AM’s broader sustainability goals. Through these initiatives, this research theme seeks to position AM as a key enabler of sustainable manufacturing, addressing both environmental impact and economic viability.

This project aims to develop a new class of (Ti-Cu)-based alloys featuring high strength, high toughness, and high hydrogen-embrittlement resistance specifically for additive manufacturing (AM).

Dr Tu Le, Email: tu.le@rmit.edu.au

Dr Mladenko Kajtaz, Email: mladenko.kajtaz@rmit.edu.au

RMIT University acknowledges the people of the Woi wurrung and Boon wurrung language groups of the eastern Kulin Nation on whose unceded lands we conduct the business of the University. RMIT University respectfully acknowledges their Ancestors and Elders, past and present. RMIT also acknowledges the Traditional Custodians and their Ancestors of the lands and waters across Australia where we conduct our business - Artwork 'Sentient' by Hollie Johnson, Gunaikurnai and Monero Ngarigo.

More information